In the world of high-stakes engineering and manufacturing, where a single micron can define the success or failure of a critical component, tight tolerance CNC machining services are not just a luxury—they are a fundamental requirement. At Dongguan Huade Precision Manufacturing Co., Ltd., we understand that precision is the foundation of innovation. This is not merely about making a part; it’s about flawlessly executing a design that pushes the boundaries of possibility.

This guide will demystify the complex world of high-tolerance machining, explaining why it’s critical, what it takes to achieve it, and how our expertise provides the reliable foundation for your most demanding projects.

What Defines Tight Tolerance Machining?

Tight tolerance, in simplest terms, refers to the minuscule permissible variation in a part’s dimensions, geometry, and form. While standard machining might deal with tolerances of ±0.05mm, tight tolerance CNC machining often operates at the level of ±0.005mm or even less, achieving micron-level accuracy. This level of precision is essential for parts that must fit together perfectly, function flawlessly under extreme conditions, or adhere to strict regulatory standards.

The journey to achieving such precision is fraught with challenges. It demands overcoming material instability, compensating for tool wear, managing thermal expansion, and accounting for machine rigidity—all factors that can influence the final outcome. This is where our expertise and technology become the critical difference.

Industries Where a Micron Matters: The Core Applications

The need for high-tolerance parts is ubiquitous, but it is particularly pronounced in industries where failure is not an option.

- Medical & Life Sciences: From surgical instruments to implants and diagnostic equipment, medical devices require absolute precision. We specialize in medical device CNC machining, producing parts that are not only accurate but also meet stringent biocompatibility and surface finish requirements.

- Aerospace & Defense: Every component in an aircraft or satellite must function flawlessly. We provide aerospace CNC machining for critical engine parts, structural components, and sensors, where tolerances can impact fuel efficiency, safety, and performance.

- Semiconductor & Electronics: The components in modern microchips and electronic devices are incredibly small and intricate. Our tight tolerance CNC milling capabilities are vital for producing precision fixtures, heat sinks, and housings that ensure consistent performance and reliability.

- Industrial Automation: In robotics and automated systems, highly accurate parts are necessary for smooth, repeatable motion and long-term reliability.

Our Technology: The Foundation of Micron-Level Accuracy

Achieving and maintaining micron-level accuracy is a symphony of advanced technology and skilled craftsmanship. At Dongguan Huade, our investment in state-of-the-art machinery is unwavering.

- Advanced CNC Machines: We utilize multi-axis machines, including 5-axis CNC systems, which allow us to machine complex geometries in a single setup. This reduces handling errors and improves the overall accuracy of the part. Our high-rigidity spindles and thermal stabilization systems actively combat the variables that can compromise precision.

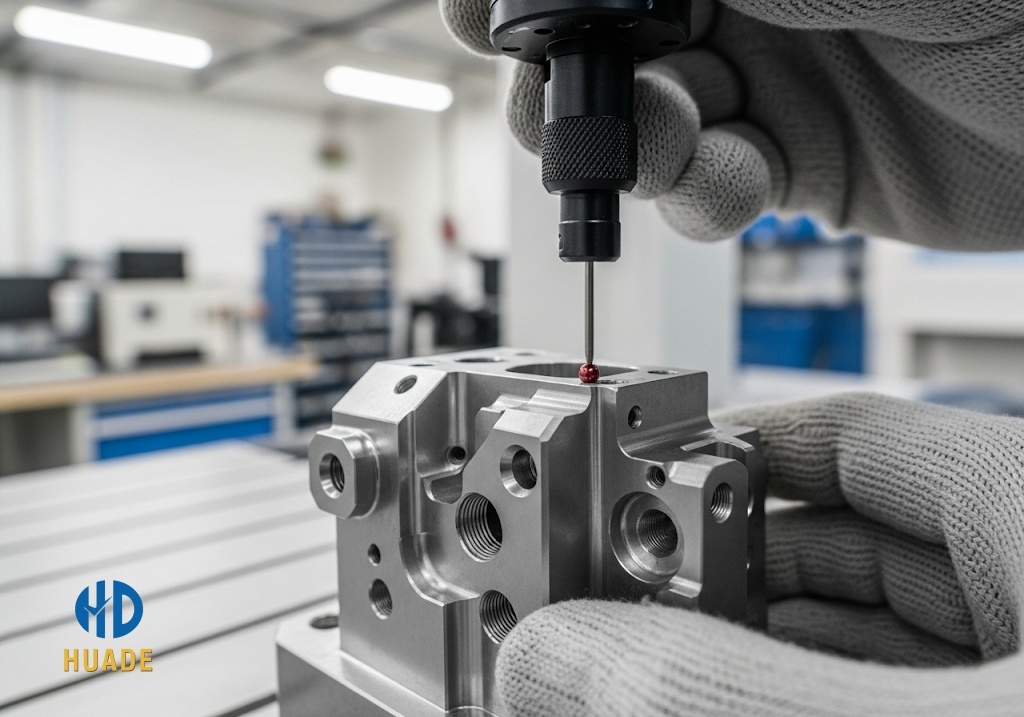

- Precision Metrology: It’s not enough to machine a part accurately; you must also be able to measure it. We employ advanced metrology equipment, including Coordinate Measuring Machines (CMMs) with sub-micron resolution, optical comparators, and laser scanners. This rigorous process ensures that every part we deliver is a testament to our quality pledge.

- Specialized Tooling & Materials: Our engineering team meticulously selects the optimal tooling and cutting strategies for each material, whether it’s hardened steel, titanium, or aluminum. We understand how different materials behave under stress, heat, and vibration, allowing us to proactively solve potential challenges.

More Than Just Machining: The GD&T Difference

Our commitment to tight tolerance CNC machining services goes beyond the machine itself. We speak the language of engineers through our deep knowledge of Geometric Dimensioning and Tolerancing (GD&T). This precise symbolic language allows us to interpret complex technical drawings and ensure that critical features like true position, flatness, and parallelism are perfectly maintained. By partnering with us, you are working with a team that understands not just the how, but the why behind every tolerance callout.

Why Choose Dongguan Huade Precision Manufacturing Co., Ltd. for Your Next Project?

Your project demands precision, and our mission is to deliver it. Our tight tolerance CNC machining services are built on a foundation of technology, expertise, and an uncompromising commitment to quality.

Whether you require CNC prototyping with tight tolerances for a proof-of-concept or need large-scale production of critical components, we offer a seamless, end-to-end solution. Our team collaborates with you from the initial design phase to final inspection, providing valuable feedback and ensuring manufacturability without sacrificing performance. We don’t just meet specifications; we exceed them.

Ready to Elevate Your Project with Unmatched Precision?

Don’t let subpar manufacturing limit your innovations. Partner with a company that makes precision its priority.

Visit www.hdproto.com to explore our capabilities or contact us today to discuss your specific tight tolerance project needs. Our team is ready to turn your most demanding designs into reality.