Introduction – Key Considerations for Machining Nylon and PTFE

When working with engineering plastics such as nylon and PTFE, designers often face questions about material selection, machining processes, and performance differences. For instance, is nylon and polyamide the same? How does PTFE machining compare to machining nylon? In CNC part production, understanding these distinctions is crucial for achieving precise tolerances, optimal performance, and cost efficiency.

Is Nylon and Polyamide the Same?

From a materials science perspective, nylon is a generic name for a family of synthetic polymers known as polyamides.

- Polyamide is the chemical term, while nylon is the common trade name.

- The most common grades are Nylon 6 and Nylon 6/6, each with slightly different mechanical properties.

- For CNC machining, both share high strength, excellent wear resistance, and good machinability, but moisture absorption rates and thermal stability may vary between grades.

Design Tip: When preparing CAD files for CNC machining nylon, specify the exact grade to ensure machinists choose cutting tools and feeds suitable for that material’s hardness and thermal properties.

Machining Nylon – Challenges and Solutions

Nylon machining offers good dimensional stability, but it requires careful control of cutting parameters:

- Thermal Sensitivity: Excessive heat during cutting can cause deformation. Use sharp tools and light cuts.

- Moisture Absorption: Nylon can absorb water, causing slight dimensional changes. Store material properly before machining.

- Tool Choice: Carbide end mills with polished flutes reduce friction and improve chip evacuation.

Design Tip: For CNC nylon parts with tight tolerances, account for potential post-machining shrinkage, especially in thin-walled geometries.

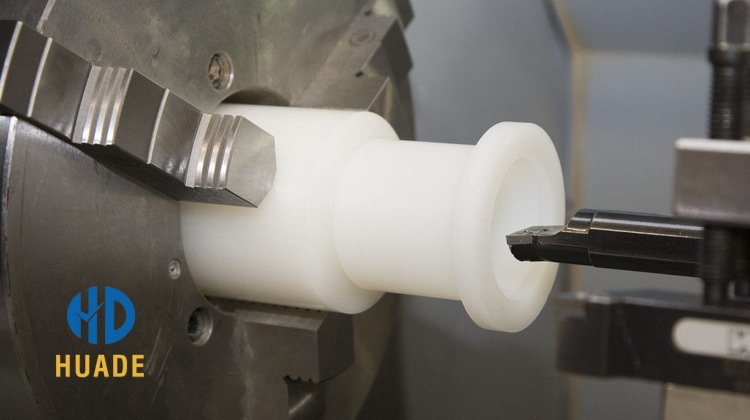

PTFE Machining – Unique Properties in CNC Processing

PTFE machining (commonly known by the trade name Teflon) differs significantly from machining nylon:

- Low Friction: PTFE’s coefficient of friction is among the lowest of any solid material, making it ideal for sealing surfaces and sliding components.

- Softness and Flexibility: PTFE can deform easily under cutting forces, so fixturing must be secure.

- Thermal Resistance: It withstands higher continuous use temperatures than nylon.

Design Tip: When designing CNC parts for PTFE machining, increase wall thickness where possible to reduce deflection and improve dimensional stability during cutting.

Choosing Between Nylon and PTFE for CNC Parts

When deciding between machining nylon and PTFE machining, consider:

- Wear Resistance: Nylon is better for structural load-bearing applications.

- Chemical Resistance: PTFE offers superior resistance to acids, bases, and solvents.

- Dimensional Tolerance: Nylon can hold tighter tolerances if moisture is controlled. PTFE may require post-machining dimensional checks due to material creep.

Design Tip: For mixed-material assemblies, ensure mating surfaces consider differences in thermal expansion between nylon, PTFE, and metals.

CNC Design Recommendations for Engineering Plastics

Regardless of whether you are machining nylon, PTFE machining, or working with other polyamides:

- Fillets over Sharp Corners: Reduce stress concentration.

- Avoid Excessive Thin Walls: Increases part rigidity during machining.

- Optimize Toolpath Strategy: Reduce heat and deformation.

- Surface Finish Considerations: Adjust feeds for desired smoothness without overheating.

Final Thoughts

Understanding whether nylon and polyamide are the same, and knowing the differences between machining nylon and PTFE machining, empowers engineers and designers to make better material and process decisions. With careful planning, the right tooling, and attention to each material’s unique characteristics, CNC-machined plastic parts can achieve both functional performance and cost efficiency.

Contact Us for CNC Machining Solutions

If you are working on a project that involves machining nylon, PTFE machining, or need expert advice on nylon vs polyamide for CNC components, our team can provide the technical insight and manufacturing capabilities to bring your designs to life.

You can learn more or discuss your specific requirements by visiting our website hdproto.com or sending us an inquiry directly through our contact page. We are always ready to help you optimize your designs for the best machining results.