In modern manufacturing, aluminium turned parts have become a cornerstone for industries requiring a balance of light weight, strength, and tight tolerances. From aerospace fittings to consumer electronics housings, these components deliver reliable performance while enabling efficient production. This article explains the advantages of aluminum machined components, best practices in production, and how choosing the right partner for aluminum precision machining can reduce cost and improve product quality.

What are aluminium turned parts?

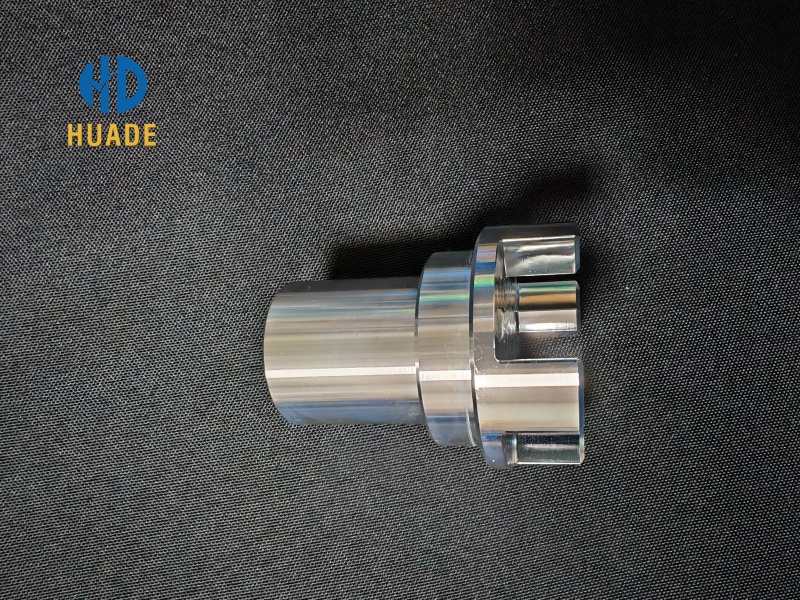

Aluminium turned parts are components produced primarily on turning centers and lathes, where a rotating workpiece is machined to precise dimensions by cutting tools. Turning is ideal for cylindrical and symmetric geometries, making it the preferred method for shafts, spacers, standoffs, and many other profiles. When manufactured correctly, these aluminium parts offer exceptional concentricity and surface finish, often at lower cost than comparable machining methods.

Key benefits

- Weight-to-strength ratio: Aluminium is significantly lighter than steel but still offers high specific strength. This makes these machined aluminium patts ideal where mass reduction matters—such as in automotive and aerospace assemblies.

- Corrosion resistance and finish: With appropriate alloys and surface treatments, aluminium parts resist corrosion and accept coatings easily, improving longevity and aesthetics.

- Thermal and electrical properties: Many electronic and thermal-management applications benefit from aluminium’s thermal conductivity, making such aluminium components common in heat-sink and connector components.

- Cost-effective high-volume production: CNC turning is highly repeatable. For mid-to-high volume runs, the per-piece cost of aluminium turned components is competitive compared to other processes like casting or stamping.

Design considerations for optimal turning

Good part design reduces cycle time and scrap. Key tips:

- Keep wall thicknesses consistent to avoid distortion.

- Minimize deep cavities—deep turning increases cycle time and tool wear.

- Use radiused corners instead of sharp internal corners to improve tool life.

- Specify tolerances realistically—tight tolerances increase cost; only apply them where function requires it.

Collaboration with an experienced supplier familiar with high-precision aluminum machining will ensure your designs are optimized for manufacturability and cost.

Choosing the right aluminium alloy

Different aluminium alloys offer varied machinability, strength, and finish characteristics. Common choices for turning include 6061, 6082, and 7075 series—each selected based on the end-use requirements. For detailed material properties, you can explore databases such as MatWeb, which provides extensive technical data sheets. At the same time, working with an experienced supplier in precision machining of aluminum parts ensures you choose the most appropriate alloy for both performance and cost efficiency.

Surface finishing and secondary operations

After turning, aluminium components commonly undergo finishing operations such as anodizing, passivation, bead-blasting, or chromate conversion. A consistent surface treatment not only enhances appearance but also improves corrosion resistance. When specifying finishes, coordinate with your aluminum precision machining vendor to confirm process compatibility and lead times.

Quality control and tolerances

High-precision applications demand strict inspection and quality protocols. Typical checks include:

- Dimensional inspection using CMM (coordinate measuring machine)

- Surface roughness measurement

- Concentricity and runout checks

- Hardness and material certification, when required

Suppliers who integrate quality control into the production flow reduce rework and ensure consistent delivery of turning of aluminum parts.

Applications that benefit most

Aluminium turned parts appear across many sectors:

- Aerospace: fittings, bushings, and lightweight structural components

- Automotive and electric vehicles: shafts, connectors, and thermal-management parts

- Medical devices: lightweight housings and precision connectors

- Consumer electronics: compact spacers, standoffs, and heat spreaders

A specialized subcategory, such as aluminum ramp parts used in access or mounting systems, demonstrates how tailored aluminum components serve niche functional needs. If your product requires durable, light, and precisely turned ramp components, discuss production volumes and tolerances early in the design phase.

Why partner with a specialist in aluminum precision machining?

Partnering with a supplier experienced in aluminum precision machining reduces time-to-market and minimizes surprises. Experts can recommend the best alloys, tooling strategies, and finishing processes to meet your cost targets and functional requirements. They also often provide engineering support to refine designs for manufacturability—an often overlooked step that can greatly reduce per-part cost.

Sustainability and recycling

Aluminium’s recyclability is a major sustainability advantage. Producing aluminium turned parts from recycled feedstock reduces environmental impact and energy consumption compared to primary production. When sustainability is a priority, request details about recycled content and supplier recycling practices.

Case example: from prototype to production

A typical workflow when sourcing custom aluminum lathe parts:

- Initial consultation and material selection.

- Prototype machining using CNC lathes to validate fit and function.

- Refinement of tolerances and surface finish.

- Transition to production volumes with optimized tooling and cycle time.

- Ongoing quality checks and supply-chain coordination.

Effective coordination during these stages ensures on-time delivery and consistent product quality.

Further reading and resources

For technical guidance on machining practices and standards, reputable resources include the Society of Manufacturing Engineers (SME) and manufacturing directories such as ThomasNet’s CNC turning guide. These platforms provide industry best practices, material insights, and process recommendations. To see how these standards are applied in real projects, explore our own expertise in high-precision aluminum machining, where we combine industry knowledge with practical manufacturing experience.

Conclusion

Precision turning of aluminum parts remain an efficient and reliable choice for precision components across industries. By combining thoughtful design, the right alloy, and experienced aluminum precision machining partners, companies can achieve excellent performance and cost efficiency. Whether your application needs general turned components or specific aluminum ramp parts, partnering early with a capable supplier will improve outcomes and speed up product development.

If you are looking for a trusted manufacturing partner, Dongguan Huade Precision Manufacturing Co., Ltd. provides high-precision CNC turning services with ±0.01mm tolerance, fast prototyping, and flexible low-volume to mass production. Contact us today at sales@hdproto.com to discuss your custom aluminum precision turning project.