Why CMM Inspection Services are a Game-Changer for Your Critical Parts

In the world of high-stakes engineering, the journey from a design on a screen to a finished part is a complex one. We’ve talked about the importance of tight tolerance CNC machining services, navigated the challenges of materials like titanium, understood the language of GD&T, and perfected the art of prototyping. But all these efforts hinge on one final, critical factor: flawless quality control. This is where our modern CMM inspection services become the indispensable force behind every successful project.

At Dongguan Huade Precision Manufacturing, we believe that precision CNC quality control is not a post-production chore—it is the final, unyielding line of defense. It is how we transform the promise of accuracy into a certified reality. This guide will take you beyond the machine shop floor, explaining why our advanced CMM inspection services are essential and how they guarantee the integrity of your most critical components.

The Evolving Challenge of Quality Verification

In standard manufacturing, a caliper or micrometer might suffice. But when tolerances shrink to the micron level and geometries become increasingly complex, traditional tools fall short. These methods are slow, prone to human error, and often cannot accurately measure complex features like contours, angles, and true positions defined by GD&T.

For our tight tolerance CNC machining services, this is simply not an option. A failure to accurately verify a part’s dimensions can lead to a domino effect of issues: assembly line delays, product failure, and costly recalls. This is why a sophisticated approach to quality control is not just a best practice—it is a fundamental necessity, and our CMM inspection services are the solution.

The Power of Our CMM Inspection Services: The Core of Modern Precision

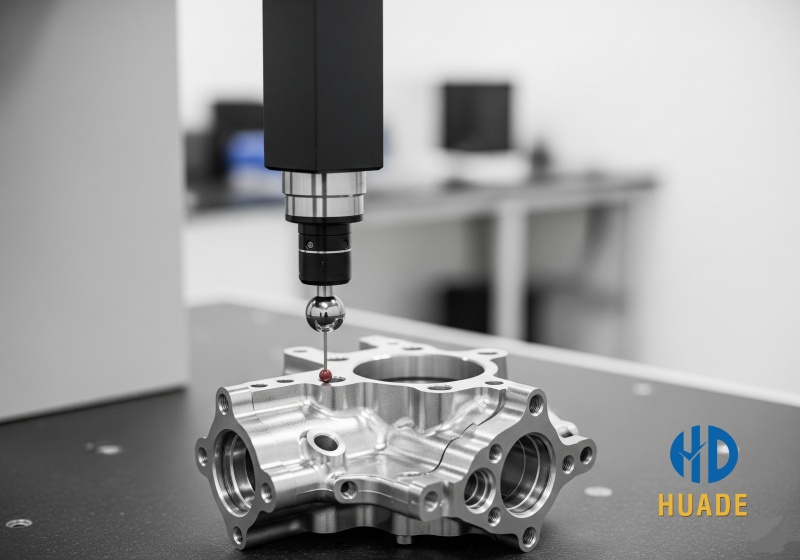

The heart of our quality assurance process is the Coordinate Measuring Machine, or CMM. A CMM is a powerful metrology tool that can measure a part’s physical geometric characteristics with extreme accuracy. It uses a sensitive probe to take a series of precise measurements, translating them into a digital map of the component.

Here’s why our CMM inspection services are a game-changer for your projects:

- Unmatched Accuracy: Our CMMs can verify dimensions and tolerances with micron-level precision, providing a level of accuracy that is impossible to achieve manually.

- Comprehensive Data: The CMM captures a complete dataset of the part, allowing us to perform thorough dimensional inspection of all features, including intricate curves and contours.

- Verification of GD&T: A CMM is specifically programmed to interpret and verify complex GD&T callouts, such as position, perpendicularity, and profile of a surface. This ensures that the part not only meets its specified dimensions but also its functional requirements.

- First Article Inspection (FAI): Before a production run begins, we perform a first article inspection (FAI) using our CMM to ensure that the initial part is perfect. This gives us the confidence to proceed with the entire batch.

Our Integrated Quality Management System (QMS)

At Dongguan Huade, quality control is not a separate department—it’s a mindset. Our robust quality mangement system (QMS) is a continuous process, not just a final check. We are committed to upholding the highest standards of quality, and our certifications (such as ISO 9001, if applicable) are a testament to this promise.

Our quality assurance process is built around our CMM inspection services and includes:

- Process Control: We use in-process monitoring to track and adjust for variables like tool wear and thermal expansion, ensuring that quality is built into the part from the very first cut.

- Skilled Personnel: Our quality engineers are not just technicians; they are experts in GD&T and metrology. They work with you to understand your part’s critical features and create a customized inspection plan.

- Comprehensive Reporting: Every inspection comes with a detailed and easy-to-understand report. This report serves as verifiable proof of our tight tolerance verification, giving you complete confidence in the integrity of the delivered part.

Why Our CMM Inspection Services Matter for Your Business

By partnering with us, you are not just getting a part; you are getting the assurance of a flawlessly manufactured component. Our commitment to precision CNC quality control saves you from the risks and costs associated with inaccurate parts. It ensures that your prototypes validate your designs, your assemblies fit together perfectly, and your products perform exactly as intended.

The final inspection is the moment of truth. With our advanced CMM technology and dedicated quality team, you can trust that your critical parts are always ready for their moment.

Ready to ensure your projects are built to perfection from start to finish?

Visit www.hdproto.com to learn more about our comprehensive CMM inspection services and how our commitment to quality can benefit your next project. Contact us today to request a free quote and a consultation.