With the growing demand for high-quality robot parts, driven by advancements in automation, artificial intelligence, and industrial applications. Whether you’re building prototypes for innovative startups or maintaining large-scale robotic systems in manufacturing plants, robotics parts form the backbone of functionality and reliability. This is where CNC (Computer Numerical Control) machining plays a pivotal role, offering precision engineering that transforms raw materials into intricate components for robotics. By leveraging CNC processes, manufacturers can produce parts of robot with exceptional accuracy, ensuring seamless integration and optimal performance. In this article, we explore how CNC machining enhances the production of basic parts of the robot, including robot spare parts and components, while providing practical guidance for engineers and businesses seeking to optimize their workflows.

Understanding CNC Machining and Its Relevance to Robot Parts

CNC machining is a subtractive manufacturing technique that uses computer-controlled tools to remove material from a workpiece, creating precise shapes and features. Unlike traditional manual methods, CNC systems follow digital instructions from CAD (Computer-Aided Design) files, enabling repeatable and complex operations such as milling, turning, and drilling. In the context of robot parts, this technology is indispensable because these parts often require tight tolerances—sometimes as fine as ±0.001 inches—to ensure smooth motion, load-bearing capacity, and durability.

For instance, robotics parts like joints, gears, and end-effectors must withstand repetitive stress and environmental factors, making material selection and dimensional accuracy critical. CNC machining excels here by accommodating a wide range of materials, including metals (aluminum, titanium, stainless steel) and plastics (ABS, nylon), which are commonly used in robotics. This versatility allows for the creation of lightweight yet robust robot parts that contribute to energy efficiency in robotic systems. Moreover, the process supports rapid prototyping, where engineers can iterate designs quickly, reducing time-to-market for new robotic innovations.

From an academic perspective, the integration of CNC in robotics manufacturing aligns with principles of lean production and Industry 4.0, emphasizing automation and data-driven optimization. By minimizing human error, CNC ensures consistency across batches, which is particularly beneficial for producing robot spare parts that need to match original specifications exactly.

CNC robotic arms machining high-precision robot parts in a modern smart factory, illustrating how CNC drives automated robotics manufacturing.

Understanding CNC Machining and Its Relevance to Robot Parts

CNC machining is a subtractive manufacturing technique that uses computer-controlled tools to remove material from a workpiece, creating precise shapes and features. Unlike traditional manual methods, CNC systems follow digital instructions from CAD (Computer-Aided Design) files, enabling repeatable and complex operations such as milling, turning, and drilling. In the context of robot parts, this technology is indispensable because such components often require tight tolerances—sometimes as fine as ±0.001 inches—to ensure smooth motion, load-bearing capacity, and durability.

For instance, robot components like joints, gears, and end-effectors must withstand repetitive stress and environmental factors, making material selection and dimensional accuracy critical. CNC machining excels here by accommodating a wide range of materials, including metals (aluminum, titanium, stainless steel) and plastics (ABS, nylon), which are commonly used in robotics. This versatility allows for the creation of lightweight yet robust robotics parts that contribute to energy efficiency in robotic systems. Moreover, the process supports rapid prototyping, where engineers can iterate designs quickly, reducing time-to-market for new robotic innovations.

From an academic perspective, the integration of CNC in robotics manufacturing aligns with principles of lean production and Industry 4.0, emphasizing automation and data-driven optimization. By minimizing human error, CNC ensures consistency across batches, which is particularly beneficial for producing these spare parts that need to match original specifications exactly.

Key Benefits of CNC Machining for Robot Parts Production

The advantages of CNC machining extend beyond basic fabrication, offering tangible impacts on quality, cost, and scalability in the robotics sector. One primary benefit is enhanced precision and consistency. Robotic systems demand parts with minimal deviations to prevent failures in critical applications, such as surgical robots or autonomous vehicles. CNC’s automated control achieves this by executing complex geometries that would be challenging or impossible manually, resulting in these parts that fit perfectly and perform reliably over time.

Another significant advantage is speed and efficiency. Traditional machining can be labor-intensive and time-consuming, but CNC reduces lead times dramatically—often producing such parts in as little as two days. This is especially valuable for spare parts, where downtime in robotic operations can lead to substantial losses. For example, in manufacturing environments, quick replacement of worn robot coupe spare parts minimizes production halts, boosting overall throughput.

Cost-effectiveness is also a key influencer. While initial setup for CNC might involve programming and tooling, the long-term savings are evident through reduced waste and lower labor costs. CNC’s ability to handle low-volume runs without expensive molds makes it ideal for custom components, where buyers seek tailored solutions without committing to mass production. Platforms offering advanced manufacturing often rely on CNC to provide instant quotes and DFM (Design for Manufacturability) feedback, empowering users to refine designs before fabrication. This democratizes access to high-end manufacturing, inspiring small enterprises and hobbyists to innovate in robotics.

Furthermore, CNC machining promotes material efficiency and sustainability. By optimizing tool paths, it minimizes scrap, aligning with eco-friendly practices in robotics development. In applications like climate technology robots, where lightweight components reduce energy consumption, CNC’s precision helps achieve these goals without compromising strength.

From a guidance standpoint, engineers should prioritize CNC for projects involving high-stakes reliability. Consider conducting simulations in software like SolidWorks to predict outcomes, then transitioning to CNC for physical validation. This approach not only mitigates risks but also fosters creative problem-solving in robotic design.

Applications of CNC Machining in Robot Spare Parts and Robotic Components

CNC machining’s influence is particularly pronounced in specialized areas such as robot coupe spare parts and robotic components. Robot spare parts—components like sensors, actuators, and frames—often require on-demand production to address wear and tear. CNC enables the fabrication of these parts with exact replicas of originals, ensuring compatibility and extending the lifespan of robotic systems. In industries like aerospace and medical robotics, where failure is not an option, CNC’s role in producing durable spare parts for robot enhances safety and operational continuity.

The demand for these components in diverse applications has further amplified CNC’s impact. These components, ranging from intricate gears to robust chassis, are critical for robotic functionality across sectors like manufacturing and research. CNC integrates here by supporting diverse processes, from 3-axis milling for simple brackets to 5-axis machining for intricate robotic arms. This accessibility inspires innovation; for instance, researchers developing swarm robotics can source components for robotics quickly, accelerating experimentation and discovery.

A practical application is in machine-tending robots, where CNC-machined robotics parts improve automation in factories. By tending CNC machines themselves, these robots create a synergistic loop, increasing productivity while reducing human exposure to hazards. This highlights CNC’s dual role: not only in manufacturing robot parts but also in enabling robots to enhance manufacturing processes.

To guide practitioners, evaluate suppliers based on certifications like ISO 9001 and their CNC capabilities. Opt for those offering material traceability and quality inspections to ensure parts meet robotic standards. This strategic selection can prevent costly revisions and inspire more ambitious projects.

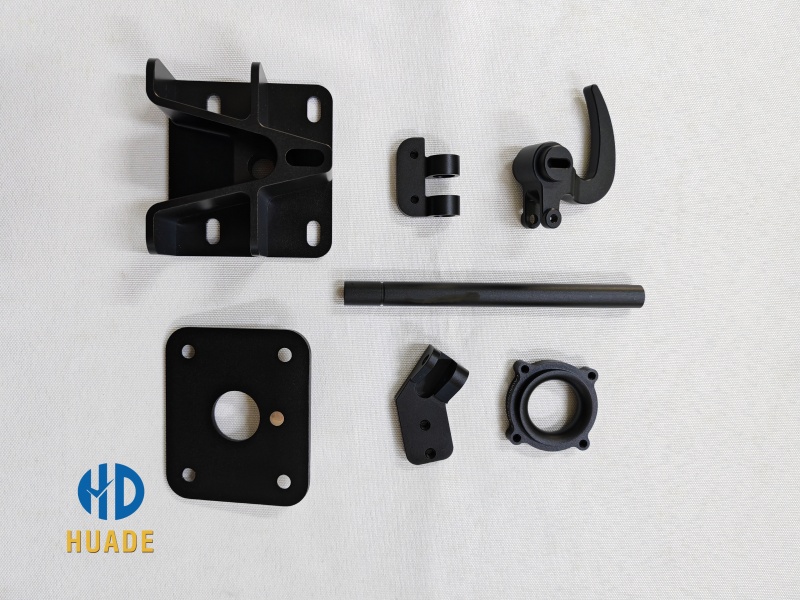

CNC-machined gears, grippers and actuator housings for industrial robots, ideal for custom robot parts and spare components.

Case Studies and Inspirational Insights

Real-world examples underscore CNC’s transformative effects. In the development of collaborative robots (cobots), CNC has been used to machine lightweight aluminum frames, reducing weight by up to 30% while maintaining structural integrity of robotic components. This has positive implications for human-robot interaction in workplaces, promoting safer and more efficient environments.

Another case involves spare parts for robot for industrial arms in automotive assembly lines. By employing CNC for rapid replacements, companies have reported up to 50% reductions in downtime, illustrating the economic benefits. Such outcomes inspire engineers to adopt hybrid approaches, combining CNC with additive manufacturing for hybrid parts for robotics that leverage the strengths of both.

Looking ahead, as robotics integrates more AI and IoT, CNC will evolve to support smarter, adaptive these components. This prospect encourages ongoing education in digital fabrication, urging professionals to explore certifications in CNC programming for competitive edges.

Embracing CNC for Advancing Robot Parts Innovation

In summary, CNC machining is a cornerstone in the production of robot parts, offering precision, speed, and cost savings that propel the robotics industry forward. Its positive influences on robot spare parts and robotic components—from ensuring reliability to enabling global accessibility—provide a foundation for sustainable growth. By adopting CNC, businesses and innovators can overcome manufacturing challenges, fostering breakthroughs in fields like healthcare and automation.

For those inspired to act, start by auditing your current for robotics needs and consulting with CNC experts. This proactive step not only enhances project outcomes but also contributes to the broader advancement of robotics technology. As we move into an era of intelligent machines, embracing CNC’s capabilities will be key to building resilient, high-performing systems.

At Dongguan Huade Precision Manufacturing Co., Ltd., we specialize in CNC machining solutions for robotics, automation, and industrial applications. With years of experience serving clients in over 30 countries, we provide:

- Custom and standard any parts for robot machining with tight tolerances.

- Flexible production for prototypes and bulk orders.

- Reliable global delivery and professional support.

To learn more about our robot spare parts and custom robotic components, visit www.hdproto.com or send us an inquiry at sales@hdproto.com.