Table of Contents

The journey from a digital design to a physical product is filled with potential challenges, and for engineers and manufacturers, one of the most critical stages is the assembly of machined parts. This process, while seemingly straightforward, can reveal hidden design flaws, tolerance issues, and integration problems. This is where rapid prototyping plays an indispensable role, providing a powerful tool to validate designs and ensure seamless assembly before committing to final production.

Understanding the Challenge: Assembling Machined Parts

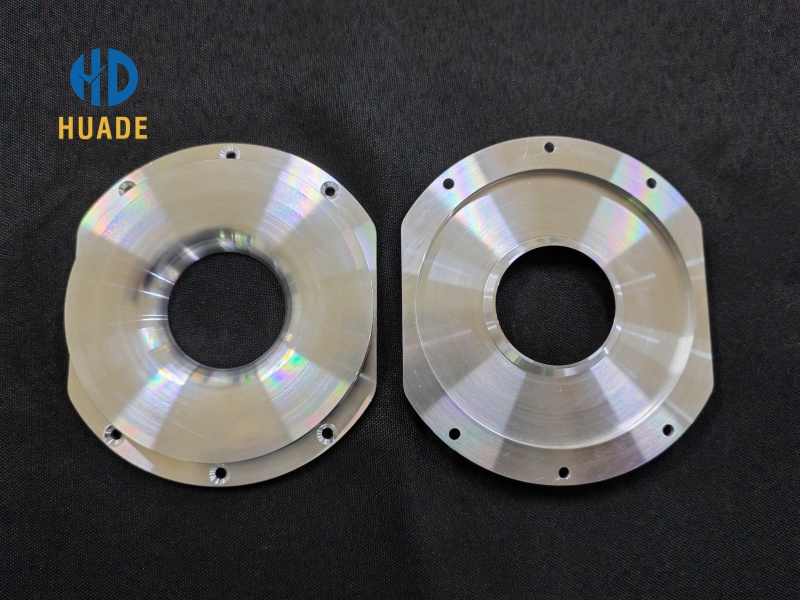

The term “assembly of machined parts” refers to the process of combining two or more components that have been manufactured using precision machining techniques like CNC milling, turning, and grinding. The success of this process hinges on the accuracy of each individual part and how they fit together. Even a tiny deviation in tolerance can lead to a domino effect of issues, from poor performance and structural weakness to complete assembly failure.

Common challenges include:

- Tolerance Stack-Up: The cumulative effect of individual part tolerances, which can cause a final assembly to fall outside of specifications.

- Interference Fits: Parts that are designed to fit tightly may bind or require excessive force to assemble if not prototyped correctly.

- Component Misalignment: Issues with how parts align with each other, leading to functional or aesthetic problems.

- Validation of Sub-Assemblies: Ensuring that smaller groups of parts fit and function correctly before integrating them into a larger product.

These challenges highlight why relying solely on 2D drawings or 3D models is not enough. A physical prototype is often the only way to catch these issues in a real-world scenario.

A Case Study in Rapid Prototyping: Validating a Medical Device Assembly

A medical device company was developing a new diagnostic tool that required a complex assembly of machined parts, including a main aluminum housing, several internal stainless steel brackets, and intricate plastic sensor mounts. The design was precise on paper, but the engineering team was concerned about the final fit and function.

They decided to use rapid prototyping to create a functional prototype before moving to full-scale production.

Step 1: Prototyping Critical Components The team used Fused Deposition Modeling (FDM) 3D printing to create the first iteration of the plastic sensor mounts. This allowed them to test the fit with the aluminum housing without the cost and lead time of machining the final material. They quickly discovered a slight misalignment in the mounting holes, which was easily corrected in the CAD model.

Step 2: Testing Sub-Assemblies Using Selective Laser Sintering (SLS) for a more durable prototype, they created the stainless steel brackets. This allowed them to test the integration of the brackets within the aluminum housing and validate their strength under load. They found that a specific bracket design caused minor interference, which they were able to quickly redesign and re-prototype.

Step 3: Final Assembly Validation Once the individual components were refined, the team used a combination of CNC machining for the main aluminum housing and 3D printing for the complex internal parts to create a final, functional prototype. This prototype allowed them to:

- Verify Fit and Finish: They could physically check how all the parts fit together, ensuring a seamless aesthetic.

- Test Functionality: They ran a series of functional tests to confirm that the device worked as intended, with no binding or misalignment issues.

- Identify Assembly Issues: They found that the assembly process itself was more complex than anticipated and were able to simplify it for final manufacturing, saving time on the production line.

This case study of rapid prototyping demonstrates its immense value. By catching issues early, the company avoided costly rework, material waste, and significant delays in bringing their product to market.

Integrating Rapid Prototyping into Your Workflow

For any project involving the assembly of machined parts, incorporating rapid prototyping is a smart strategic move. It is not just about making a physical part; it’s about validating an entire system. By creating physical prototypes, engineers can:

- Detect Design Flaws: Identify issues that are invisible in a 3D model.

- Validate Tolerances: Ensure parts fit and function correctly, especially with close tolerances.

- Test Functionality: Confirm that the final product works as intended in a real-world environment.

- Streamline the Assembly Process: Discover and solve assembly line challenges before they arise.

The investment in prototyping is a small price to pay to avoid the much larger costs of tooling changes, production delays, and product recalls.

The Path to Perfect Assembly

The successful assembly of machined parts is a testament to meticulous design and precise execution. However, perfection is rarely achieved on the first try. By embracing rapid prototyping, manufacturers and engineers can gain the confidence to move forward with production, knowing that their designs have been thoroughly tested and validated. This approach not only saves time and money but also leads to higher-quality, more reliable products. It’s a key part of the modern manufacturing workflow that transforms digital concepts into flawless physical realities.

Ready to Perfect Your Machined Parts and Prototypes?

Whether you need rapid prototyping, assembly of machined parts, or precision CNC machining support, our engineering team is here to help you move from concept to flawless production.

📧 Email: sales@hdproto.com

🌐 Website: https://hdproto.com

Let’s work together to transform your design into a precise, high-quality finished product.

💬 Ready to discuss your CNC project?

Fill out the form below and our engineering team will get back to you within 24 hours.