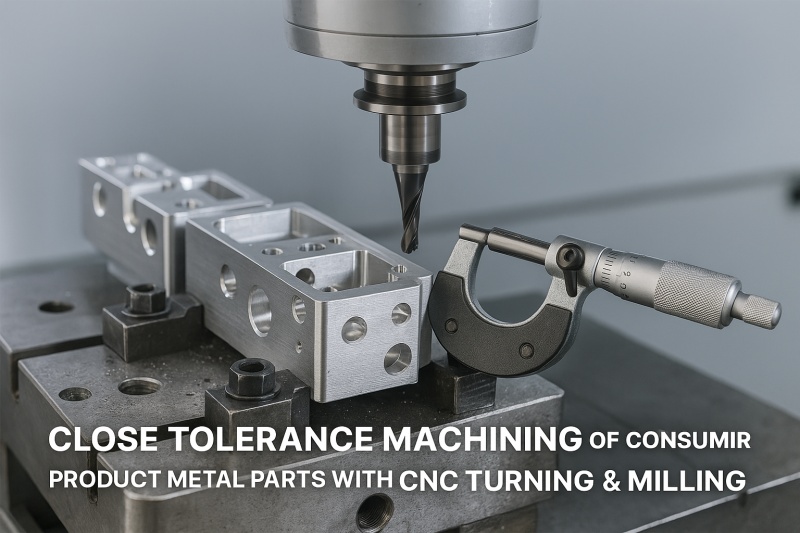

Close Tolerance Machining Overview

Close tolerance machining is where engineering intent meets production reality. For consumer brands, it is the difference between parts that merely fit and parts that align, seal, and look consistent at scale. HDPROTO integrates CNC milling and turning into one controlled flow so critical features regularly meet ±0.01 mm while cosmetic zones achieve uniform textures and color. We support fast 2–3-day prototyping on selected geometries, low MOQs for pilot runs, and inspection documentation that keeps quality measurable and repeatable.

What “Close Tolerance” Means in Practice

Tight numbers on a drawing are only the beginning. Holding close tolerance requires stable fixturing, thermal control, controlled tool wear, hygienic chip evacuation, and metrology built into the routine. We focus the tightest tolerance where it changes function: sealing faces, bearing fits, locating datums, and positional patterns that govern alignment. On non-functional surfaces we recommend pragmatic limits so cost remains under control. This balance lets you hit the performance spec without over-engineering the rest of the part.

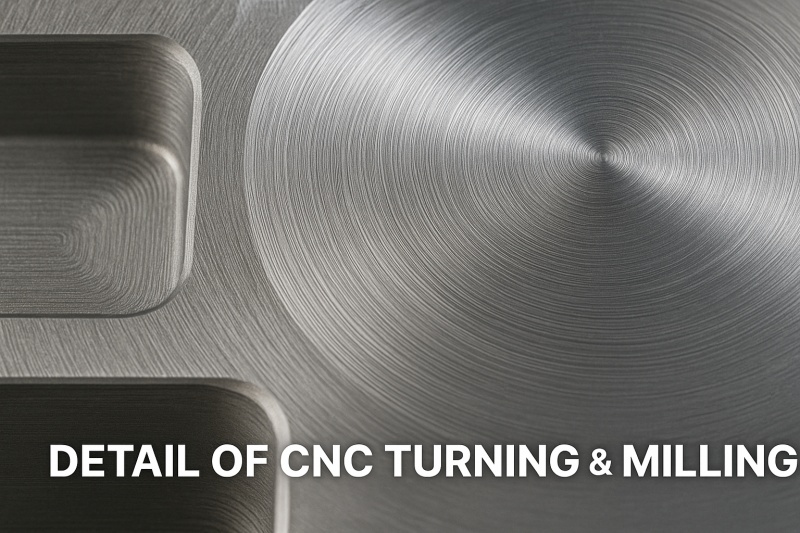

For consumer product metal parts, the requirement is two-fold: parts must interchange dimensionally across batches and present a consistent visual standard on the shelf. We validate both. Functional features are measured against GD&T callouts, while cosmetic areas are qualified against controlled surface prep and finishing panels under consistent lighting. The result is high first-pass yield and predictable cost at launch.

CNC Milling and Turning—One Controlled Flow

Our cells combine 3–5-axis milling with mill-turn capability to reduce setups and stack-up error. We use in-process probing to pick up datums, verify tool offsets, and maintain positional accuracy on hole patterns and pocket arrays. For thin-wall housings and covers we apply balanced toolpaths and adaptive step-downs to protect geometry without over-clamping. Coaxiality for shafts and hubs, perpendicularity on stepped housings, and true-position on multi-hole features are checked during machining, not just at final inspection, so drift is corrected before it becomes scrap.

When a part moves from prototype to small-batch, we lock the proven recipe: fixtures, cutters, coolant strategy, speeds and feeds, and inspection frequency. That is how we keep the first-article behavior consistent as volume grows and how we avoid the hard reset that often happens when processes are re-created from memory.

Materials & Finishes for Consumer Product Metal Parts

We routinely machine aluminum (6061/6063/6082/7075), stainless steels (304/316/17-4PH), carbon and tool steels, brass and copper alloys, and titanium for weight-critical components. Finishes include precision bead-blast, linear brushing, Type II/III anodizing including hard coat, passivation, electroless nickel, decorative nickel/chrome, and powder coating. Each route is tuned to your brand’s cosmetic target and wear environment—pocketable devices need different textures than kitchen hardware or audio frames. Color consistency is managed through sample panels and process control, not just a single good prototype.

Where thermal performance matters, we control surface roughness and flatness on interface planes so TIMs wet correctly and heat spreaders sit flush. Where EM shielding matters, we specify compatible base alloys and plating sequences. Where touch and hygiene matter, we combine edge breaks with controlled Ra to eliminate sharpness while keeping the finish crisp and repeatable after anodizing.

Tolerances, Metrology & Documentation

Critical features can be held to ±0.01 mm depending on material, span, and geometry. We verify with CMM routines, height-gauge and gauge blocks, pin/plug gauges, and surface roughness checks. When requested, we deliver FAIR/FAI, capability studies, and full inspection reports mapped to the drawing. Sampling plans are aligned with incoming inspection on your side, and for sealing or pressure features we can run leak tests and function checks before shipment.

Documentation is not paperwork—it is how tolerance becomes durable. We keep controlled process sheets, revisioned NC programs, tool lists, and fixture drawings. That way, when you reorder or revise, we are not guessing at what made the earlier batch successful; we are rerunning a documented recipe and scaling it responsibly.

Design Guidance to Hold Tight Specs

Good drawings make good parts. Define clear primary/secondary/tertiary datums and apply GD&T where alignment and fit matter most. Avoid blanket ±0.01 mm on non-functional faces—tighten where the mechanism demands it and relax elsewhere to preserve cost and schedule. Add reliefs at pocket intersections to remove cutter dwell marks, keep thin walls practical for the alloy and finish, and specify cosmetic zones separately from function so finishing can be tuned without arguing over dimensional intent. Share early prototypes for DFM—one loop of feedback can remove hours of future setup time.

Applications

We produce device frames and bezels, hinge components, precision knobs and dials, audio and camera housings, strap and buckle hardware, heat-spreader plates, and structural inserts that must carry load without print-through. KPIs include dimensional interchangeability across builds, low cosmetic defect rates at retail inspection levels, and consistent color/texture when parts meet on the final assembly. Whether your next release is an accessory with a premium finish or a performance module that lives behind a gasket, our close tolerance machining ensures reliability and perceived quality for high-precision consumer product metal parts.

Why HDPROTO

We combine fast DFM collaboration with stable execution: CNC Milling and Turning under one roof, documented processes, and responsive engineering support. Rapid prototypes in 2–3 days for selected geometries, low MOQ to bridge development and launch, integrated finishing, and inspection that travels with the part. Materials and finish options are standardized and traceable—see Our Services for details. We ship globally with export paperwork ready and protect your IP through NDA and controlled file transfer.

Need close tolerance machining for your next consumer product? Get a fast, engineering-level response here: Request a Quote.