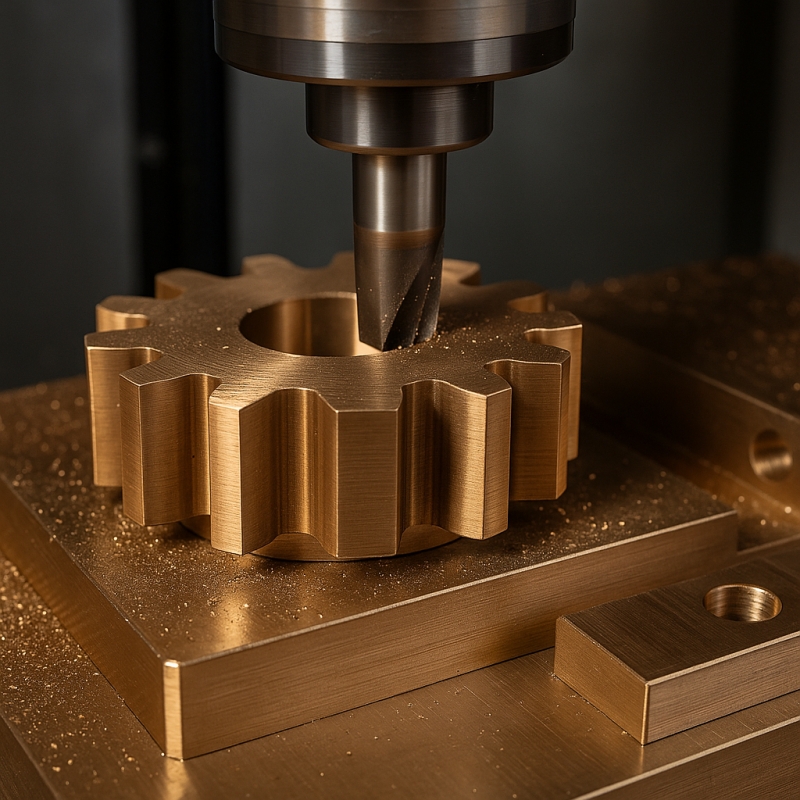

When it comes to manufacturing high-quality brass machined parts, the choice of machining technique and expertise can make the difference between success and failure. CNC brass machining has emerged as the gold standard for producing complex, precise components across industries ranging from electronics to automotive applications.

In addition to brass components, we also specialize in CNC machining bronze for demanding high-strength applications.

Understanding the Fundamentals of Machining Brass

Machining brass presents unique challenges and opportunities that distinguish it from other metals. Brass, an alloy primarily composed of copper and zinc, offers excellent machinability while providing superior corrosion resistance and aesthetic appeal. The material’s favorable cutting characteristics make it ideal for intricate brass machined parts that require tight tolerances.

The key to successful brass machining lies in understanding the material’s properties. Brass has a relatively low melting point and excellent thermal conductivity, which means heat dissipation during machining is more efficient compared to steel or aluminum. This characteristic allows for faster cutting speeds and improved surface finishes in the final product.

Advanced CNC Brass Machining for Superior Results

Modern brass CNC machining employs sophisticated programming and tooling strategies to maximize efficiency and precision. Computer numerical control systems enable manufacturers to achieve repeatability and accuracy that manual machining simply cannot match.

Critical factors in CNC brass operations include:

Tool Selection and Geometry: Sharp carbide tools with positive rake angles work exceptionally well for brass machining. The material’s tendency to produce continuous chips requires careful consideration of chip evacuation and coolant application.

Cutting Parameters Optimization: Brass allows for aggressive cutting parameters compared to harder materials. Higher spindle speeds and feed rates can be employed without compromising surface quality, resulting in reduced cycle times and improved productivity.

Workholding Solutions: The relatively soft nature of brass requires specialized workholding techniques to prevent deformation during machining operations. Soft jaws and distributed clamping forces help maintain part integrity throughout the manufacturing process.

Quality Control in Brass Machined Parts Manufacturing

Achieving consistent quality in brass machined parts requires comprehensive quality control measures throughout the production process. Dimensional accuracy, surface finish, and material integrity must all meet stringent specifications.

Modern quality control for brass components includes:

Dimensional Verification: Coordinate measuring machines (CMM) and precision gauges ensure that all critical dimensions meet blueprint requirements. The stability of brass during machining operations contributes to excellent dimensional consistency.

Surface Finish Analysis: Brass naturally achieves superior surface finishes due to its machining characteristics. Proper tool selection and cutting parameters can produce mirror-like finishes directly from the machining operation, often eliminating secondary finishing processes.

Material Certification: Ensuring the correct brass alloy composition is crucial for applications requiring specific mechanical or electrical properties. Material certificates and chemical analysis verify compliance with industry standards.

Industry Applications and Design Considerations

Brass machined parts find applications across diverse industries due to their unique combination of properties. Electronics manufacturers rely on brass components for connectors and terminals, while plumbing applications utilize brass fittings for their corrosion resistance.

Design engineers should consider several factors when specifying brass components:

Alloy Selection: Different brass alloys offer varying properties. Free-machining brass (C360) provides excellent machinability, while naval brass offers superior corrosion resistance for marine applications.

Geometric Complexity: The excellent machinability of brass allows for intricate geometries that might be challenging or impossible with other materials. However, thin walls and delicate features require careful process planning to prevent distortion.

Cost Optimization: While brass may have higher material costs than some alternatives, its superior machinability often results in lower overall manufacturing costs due to reduced cycle times and minimal secondary operations.

Future Trends in Brass CNC Machining

The evolution of brass CNC machining continues with advances in machine tool technology, cutting tool materials, and manufacturing software. Multi-axis machining centers enable the production of increasingly complex brass machined parts in single setups, reducing handling time and improving accuracy.

Automation integration, including robotic loading systems and in-process measurement, further enhances the efficiency and reliability of brass machining operations. These technological advances position brass as an increasingly attractive material choice for precision manufacturing applications.

Machining brass will continue to play a vital role in modern manufacturing, offering designers and engineers a material that combines excellent workability with proven performance characteristics. Understanding the nuances of brass machining ensures optimal results in both prototype and production environments.

For manufacturers seeking reliable, high-quality brass machined components, partnering with experienced precision machining specialists ensures access to the latest techniques and quality standards in the industry. Other popular services include CNC machining bronze for high-strength applications.

Looking for reliable CNC brass machining solutions? At Dongguan Huade Precision Manufacturing Co., Ltd, we deliver high-quality brass machined parts with advanced machining brass and precision brass machining services. Contact us today for fast quotes and global delivery.