As robotics becomes increasingly embedded in daily life, the physical components inside robots play a central role in determining their performance and reliability. Robots are no longer confined to research labs—they are active in factory floors, logistics hubs, hospitals, restaurants, and classrooms. The success of each robotic system depends on the quality, compatibility, and durability of its individual parts. From high-load mechanical joints to micro-scale sensors, every component must meet precise specifications to ensure long-term functionality and safety. For those seeking the best robot parts, understanding the fundamental categories and performance metrics is essential.

Major Categories of Robotic Components

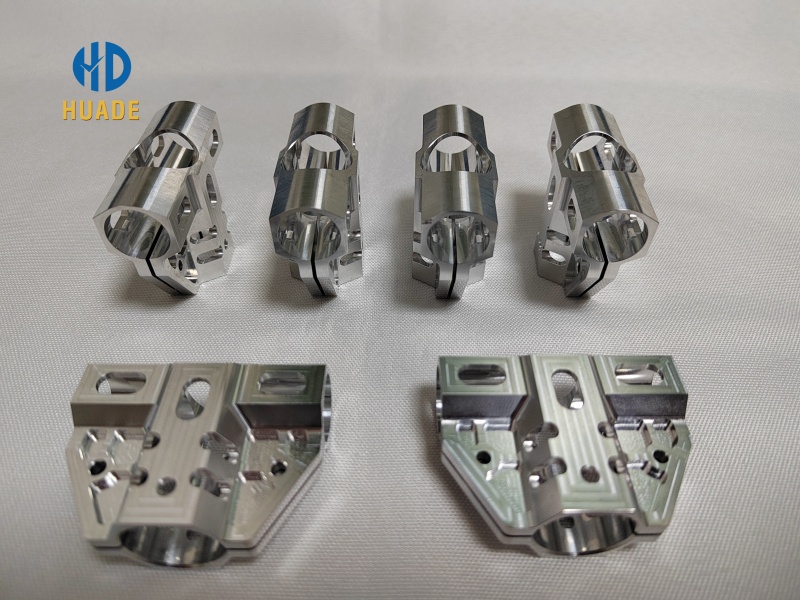

1. Structural Framework: The structure of a robot provides its form and stability. This includes machined frames, base plates, joints, and brackets made from aluminum alloys, carbon steel, or advanced polymers. These materials are selected based on strength-to-weight ratio, corrosion resistance, and machining accuracy. In mobile robots or robotic arms, maintaining dimensional precision is essential for proper alignment and repeatable motion.

2. Drive Mechanisms: Motors and actuators convert electrical signals into mechanical motion. Stepper motors offer precise incremental movement, while servo motors provide controlled rotation with feedback loops. Linear actuators allow pushing or pulling actions for lifting or positioning. Each drive type is chosen based on torque, speed, response time, and energy efficiency. For industrial tasks like painting or palletizing, actuator performance directly influences throughput and accuracy.

3. Sensor and Feedback Systems: Sensors are the eyes, ears, and skin of a robot. Proximity sensors help detect nearby objects, gyroscopes track orientation, force sensors measure resistance, and cameras provide visual input. These devices feed data into microcontrollers or PLCs, enabling the robot to make real-time decisions. Accurate sensor integration ensures better control, safety, and adaptability in complex environments.

Applications in Various Fields

Industrial Automation: In manufacturing, robots perform tasks such as welding, material handling, and inspection. Components must tolerate high heat, vibration, and repetitive stress. Structural integrity and motor durability are critical in this environment. The choice of connectors, fasteners, and bushings also affects maintenance cycles and uptime.

Service and Healthcare Robotics: Robots used in hospitals or public spaces require quiet, smooth, and clean-operating components. Lightweight materials help ensure mobility, while non-corrosive finishes support hygiene. For example, delivery robots in hospitals use compact motors and simple gear systems to navigate hallways without disturbing patients.

Education and Research: In classroom and lab environments, modular robot kits allow students to explore coding, logic, and mechanics. Simplified versions of real-world parts—such as plastic servos, snap-fit frames, and plug-in sensors—enable hands-on learning. Educational robotics focuses more on accessibility and reusability than industrial-grade performance, but the underlying engineering principles are the same. These accessible systems help beginners understand the value of core parts for robotics.

Robot Components in Fiction vs Reality

Pop culture often shows robots with imaginative parts—glowing limbs, exaggerated armor, or multifunctional attachments. While visually appealing, these designs rarely reflect engineering practicality. In real-world robotics, standardized materials, repeatable geometries, and tested tolerances ensure functionality. For example, a robotic joint must rotate precisely thousands of times without degrading, something fictional designs typically ignore. Games like Fallout 4 robot parts highlight dramatic flair, but real robotics relies on consistency, safety, and integration.

Understanding how real robot parts are selected, integrated, and maintained provides deeper insight into what makes modern robotics possible. From mechanical design to electrical control, each part must cooperate with the others to create a responsive, durable machine. Whether you’re exploring robotics as a student, an engineer, or simply a curious observer, gaining familiarity with core components is the first step to grasping this evolving technology.

Need reliable, high-precision parts for robotics?

Email us at sales@hdproto.com for a custom quote or technical support. Discover more at www.hdproto.com – your source for expert CNC machining solutions.