CNC Machining Services: The Backbone of Modern Manufacturing

CNC (Computer Numerical Control) machining represents a significant leap forward in manufacturing technology. Unlike traditional manual machining, which relies heavily on human operation, CNC machining uses computerized controls to operate machine tools with unparalleled precision. This technology has revolutionized the production of complex parts across various industries, from aerospace and automotive to medical devices and consumer electronics.

At its core, CNC machining transforms digital designs into physical components through a series of subtractive manufacturing processes. The process begins with a CAD (Computer-Aided Design) file, which is then converted into a CAM (Computer-Aided Manufacturing) program. This program guides the CNC machine tools, which can include mills, lathes, routers, and grinders, to remove material from a workpiece and create the desired shape with exceptional accuracy.

One of the key advantages of CNC machining is its ability to produce consistent parts with tight tolerances, often as low as ±0.001mm. This level of precision is crucial for industries where even the smallest deviation can compromise performance or safety. Additionally, CNC machining offers greater flexibility, allowing for quick design modifications and the production of both simple and highly complex geometries that would be challenging or impossible with traditional methods.

Our Comprehensive CNC Machining Capabilities

At Dongguan Huade Precision Manufacturing Co., Ltd., we pride ourselves on offering a wide range of CNC machining services to meet the diverse needs of our global clients. Our state-of-the-art facility is equipped with advanced CNC machines, including 3-axis, 4-axis, and 5-axis machining centers, CNC lathes, and Swiss-type lathes, enabling us to handle projects of varying complexity and scale.

Precision Milling

Our CNC milling services are ideal for producing parts with intricate shapes and features. Using 3-axis milling, we can create parts with flat surfaces, holes, and slots with high accuracy. For more complex parts, our 4-axis and 5-axis milling capabilities allow us to machine multiple sides of a workpiece in a single setup, reducing production time and improving precision. Whether you need simple brackets or complex aerospace components, our milling services can deliver the precision and quality you require.

CNC Turning

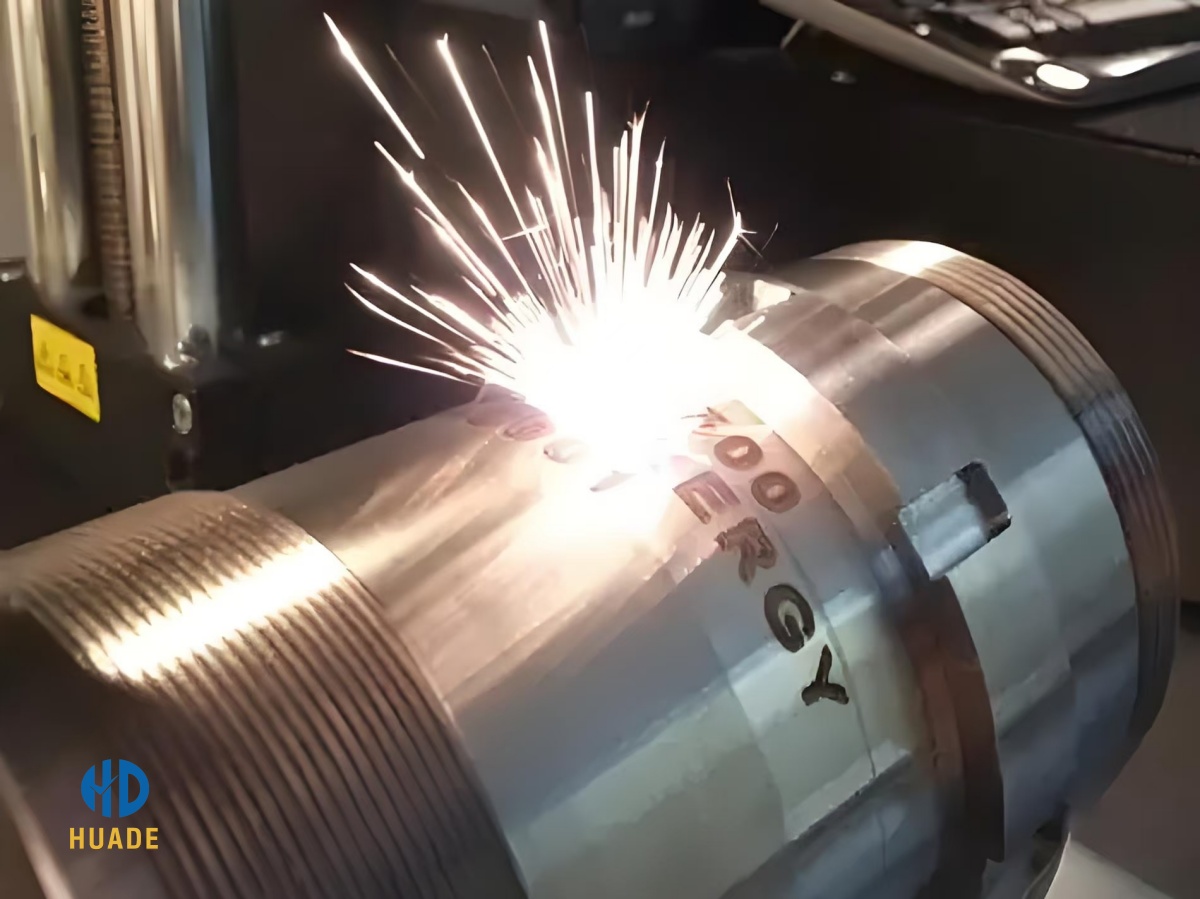

CNC turning is perfect for producing cylindrical parts, such as shafts, bushings, and fasteners. Our CNC lathes can handle workpieces of various sizes, from small-diameter components to large shafts, with exceptional surface finish and dimensional accuracy. We also offer Swiss-type turning for small, intricate parts that require tight tolerances and high production volumes. This technology allows for simultaneous machining operations, significantly reducing cycle times and increasing productivity.

Additional Machining Services

In addition to milling and turning, we offer a range of secondary machining services to complete your parts. These include drilling, tapping, threading, and grinding, as well as more specialized processes like EDM (Electrical Discharge Machining) for complex shapes and hard materials. Our team of skilled machinists can also perform assembly services, ensuring that your parts are ready for immediate use upon delivery.

Custom Part Production: Tailored Solutions for Your Unique Needs

We understand that every client has unique requirements, which is why we specialize in custom part production. Our team works closely with you from the initial concept stage to ensure that your specific needs are met. Whether you have a detailed CAD design or just a rough sketch, our engineering team can help refine your design for manufacturability, ensuring that your parts are not only functional but also cost-effective to produce.

Material Selection

We offer a wide range of materials to choose from, including metals, plastics, and composites. Our material experts can help you select the best material for your application based on factors such as strength, durability, corrosion resistance, and temperature tolerance. Common materials we work with include aluminum, stainless steel, brass, copper, titanium, and various engineering plastics like ABS, nylon, and PEEK.

Prototyping Services

Before moving into full production, we offer rapid prototyping services to help you test and validate your design. Our prototyping process allows you to evaluate the form, fit, and function of your parts, making any necessary adjustments before mass production. This not only reduces the risk of costly errors but also speeds up the overall product development cycle. We can produce prototypes using the same materials and processes as your final parts, ensuring that the prototype accurately represents the end product.

Low to High-Volume Production

Whether you need a small batch of prototype parts or large-volume production runs, we have the capabilities to meet your needs. Our flexible manufacturing system allows us to quickly switch between different part numbers and production volumes, ensuring that we can deliver your order on time, regardless of size. We also offer volume discounts for large production runs, helping you reduce your manufacturing costs.

Quality Management System

We are ISO 9001:2015 certified, which demonstrates our commitment to maintaining consistent quality standards. Our quality management system includes strict procedures for document control, process control, and corrective and preventive actions. We also conduct regular internal audits to identify areas for improvement and ensure that our quality control processes are effective.

In-Process Inspection

To catch any issues early in the production process, we perform in-process inspections at critical stages of manufacturing. This includes checking dimensions, surface finish, and material properties during machining, as well as verifying that all features meet the design requirements. By identifying and addressing problems early, we can minimize waste and ensure that your parts meet the required quality standards.

Final Inspection

Before shipping, every part undergoes a thorough final inspection. Our quality control team checks each part against the approved drawings and specifications, ensuring that all dimensions, tolerances, and surface finishes are within acceptable limits. We also perform functional testing when required, to ensure that your parts perform as expected in their intended application. A detailed inspection report is provided with each shipment, giving you complete visibility into the quality of your parts.

Delivery Management: On-Time Delivery, Every Time

We understand that on-time delivery is crucial for your business success. That’s why we have implemented a robust delivery management system to ensure that your orders are delivered when you need them. Our production planning team works closely with our manufacturing and logistics departments to create realistic production schedules and ensure that all materials and resources are available when needed.

Production Scheduling

Using advanced planning software, we create detailed production schedules that take into account the complexity of your parts, the availability of machines and operators, and your delivery requirements. We regularly review and update these schedules to ensure that they remain on track, and we communicate any potential delays to you immediately, along with a plan to mitigate them.

Supply Chain Management

We have established strong relationships with our suppliers to ensure a reliable supply of high-quality materials. Our procurement team works closely with our suppliers to monitor material availability and ensure that materials are delivered on time. We also maintain safety stocks of commonly used materials to minimize the risk of production delays due to material shortages.

Logistics and Shipping

We offer a range of shipping options to meet your needs, including express, air, and sea freight. Our logistics team works with reputable shipping companies to ensure that your parts are transported safely and efficiently. We provide real-time tracking information for all shipments, so you can monitor the progress of your order from our facility to your door. We also handle all customs documentation, ensuring that your parts clear customs quickly and without delays.

Global Service Capabilities: Serving Clients Around the World

With our headquarters in Dongguan, China, we are strategically located to serve clients around the world. We have extensive experience working with international clients, and we understand the unique challenges of global manufacturing, including language barriers, cultural differences, and international regulations.

Custom Service Solutions

Huade team specializes in delivering tailored support for every aspect of your custom CNC machining project. Whether you need personalized part design adjustments, custom production scheduling to meet tight deadlines, or specialized quality control protocols for unique components, we adapt to your specific requirements. From initial concept refinement to post-production follow-ups, we provide dedicated assistance for prototype development, material selection guidance, and volume production optimization—ensuring your custom manufacturing needs are met with precision and flexibility.

Why Choose Dongguan Huade Precision Manufacturing Co., Ltd.?

When it comes to CNC machining services, choosing the right partner is crucial. At Dongguan Huade Precision Manufacturing Co., Ltd., we offer a unique combination of expertise, technology, and customer service that sets us apart from our competitors.

Expertise and Experience

With years of experience in the CNC machining industry, our team has the knowledge and skills to handle even the most complex projects. Our engineers and machinists are highly trained and certified, and they stay up-to-date with the latest manufacturing technologies and techniques. We also invest in ongoing training to ensure that our team remains at the forefront of the industry.

Advanced Technology

Our state-of-the-art facility is equipped with the latest CNC machines and inspection equipment, enabling us to deliver the highest level of precision and quality. We regularly invest in new technology to improve our capabilities and stay ahead of the competition. This commitment to technology ensures that we can meet the evolving needs of our clients and provide innovative solutions to their manufacturing challenges.

Customer-Centric Approach

At Dongguan Huade Precision Manufacturing Co., Ltd., we put our clients first. We work closely with you to understand your unique needs and provide customized solutions that meet your specific requirements. Our team is always available to answer your questions and provide support, from the initial design stage to after-sales service. We believe that building strong, long-term relationships with our clients is the key to our success.

Conclusion

CNC machining services play a vital role in modern manufacturing, offering precision, flexibility, and efficiency that traditional methods cannot match. At Dongguan Huade Precision Manufacturing Co., Ltd., we are committed to providing comprehensive CNC machining services that help our clients turn their concepts into high-quality products. From precision milling and turning to custom part production, quality control, and global delivery, we have the capabilities and expertise to meet all your CNC machining needs.

Whether you are a small business looking for prototype parts or a large corporation requiring high-volume production, we can provide the tailored solutions you need. Contact us today to learn more about our CNC machining services and how we can help you achieve your manufacturing goals.